Glass stairs

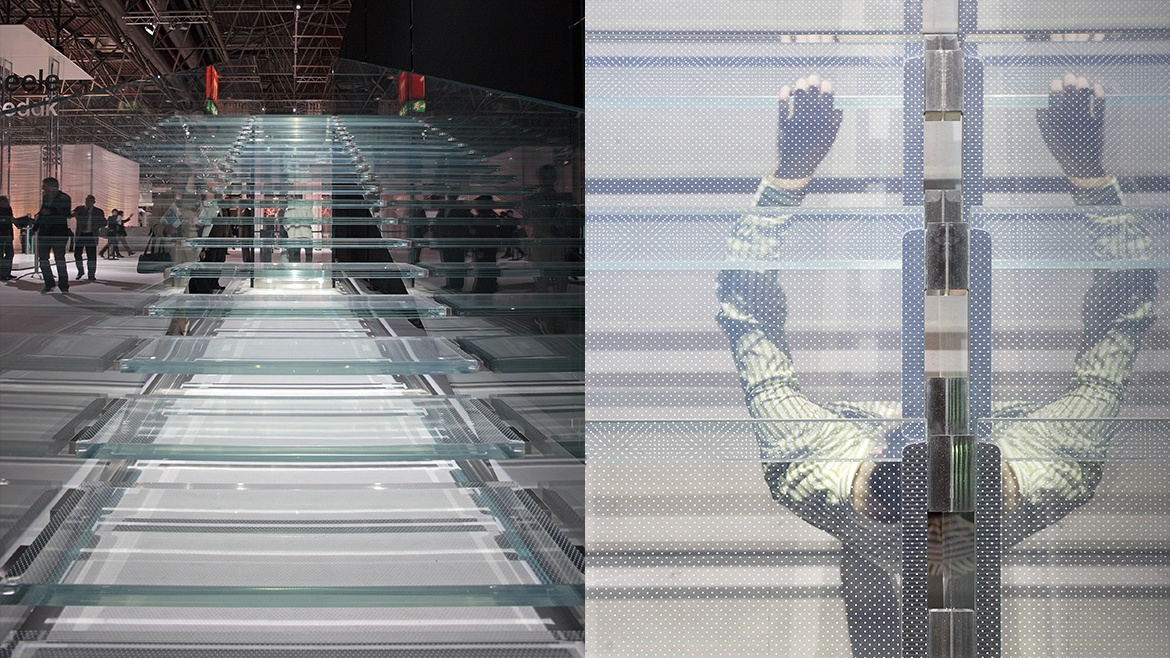

Experience from a wide variety of research projects was incorporated into the design of the staircase. The glass constructions commonly used today often still separate between linear connecting elements made of steel or aluminum and the flat glazing. This type of construction does not fully exploit the constructive potential of glass. For a holistic design approach, a frictional connection is required, for which adhesive or lamination technology is the ideal joining technique. Thanks to the novel, highly transparent processes, the glass panes appear to float in front of the minimized fitting parts required for the design - in reality they form a friction-locked unit. The joining technology allows the individual elements to be joined together to form a load-bearing overall construction, while at the same time enabling assembly and disassembly. The glass staircase is not only an object of applied research, but is also a contribution to anchoring this new technology in architecture and design.

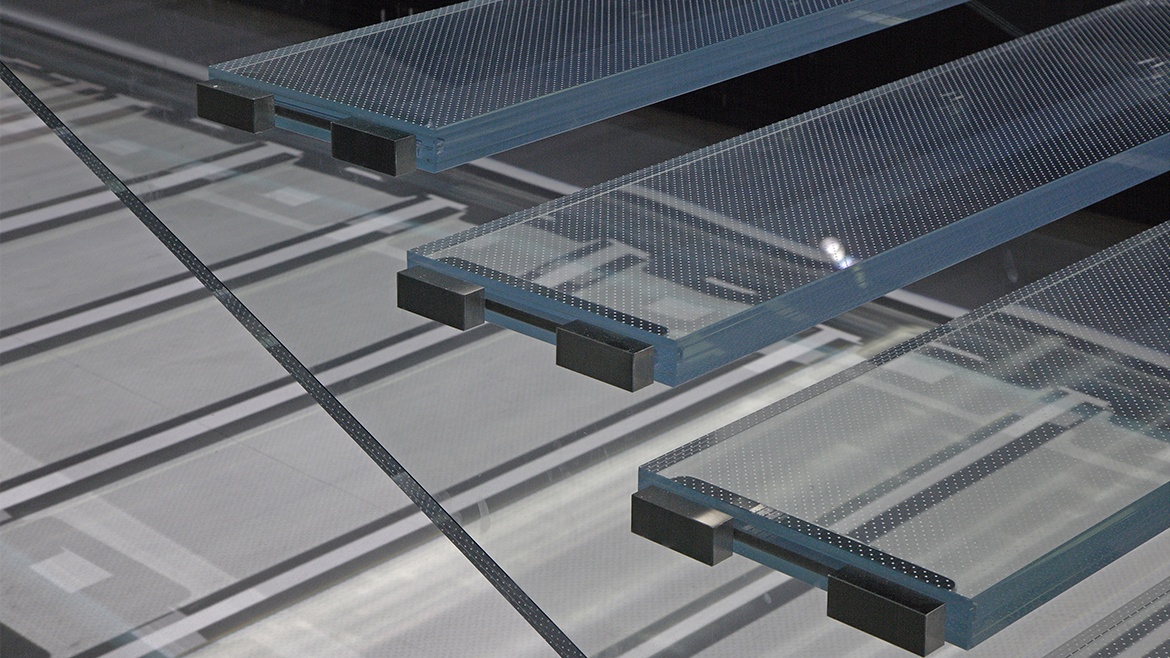

The construction was developed in close cooperation and constant dialogue between IBK Research + Development, ITKE Research and Application and the company seele. The staircase is limited to only two elements, the stringers and the horizontal steps. The stress on the stringers is divided into two essential components. Firstly, a single-span beam under vertical load with a span of 8 m and secondly a clamped banister with a horizontal load (spar load). The connection of the exclusively horizontal steps to the stringers is articulated and thus counteracts both loads. The entire staircase was developed on the basis of models and elaborate calculations with finite elements.

For the joining of the staircase three constructional details had to be solved, the lower and upper support of the stringers and the connection of the stair steps to the stringers. In constructive glass construction, drilled point supports or mechanical clamping plates are usually used for connection details. The advantage of gluing, on the other hand, is that the connection forces are introduced over a large area and thus expensive and statically difficult drillings in the glass stringers are not necessary. The elements are only connected to each other by means of frictionally laminated fitting parts. In contrast to PVB, the SGP films used here can be used for load-bearing constructions.

Even though extensive investigations regarding the aging resistance have to be carried out before this construction method can be approved in the future, the stairs show the great potential of this new adhesive technology. This was also confirmed by the Glass and Architecture Innovation Award of the Düsseldorf Trade Fair, with which the staircase was awarded, and above all by the great interest shown by visitors to the trade fair.

Duration: 2004 - 2006

IBK2 I Research + Development

ITKE

seele GmbH & Co. KG